Shifting Gears: A Different Bottom Line

27 January 2022 -

By Eric Desaulniers

Founder, President & Chief Executive Officer

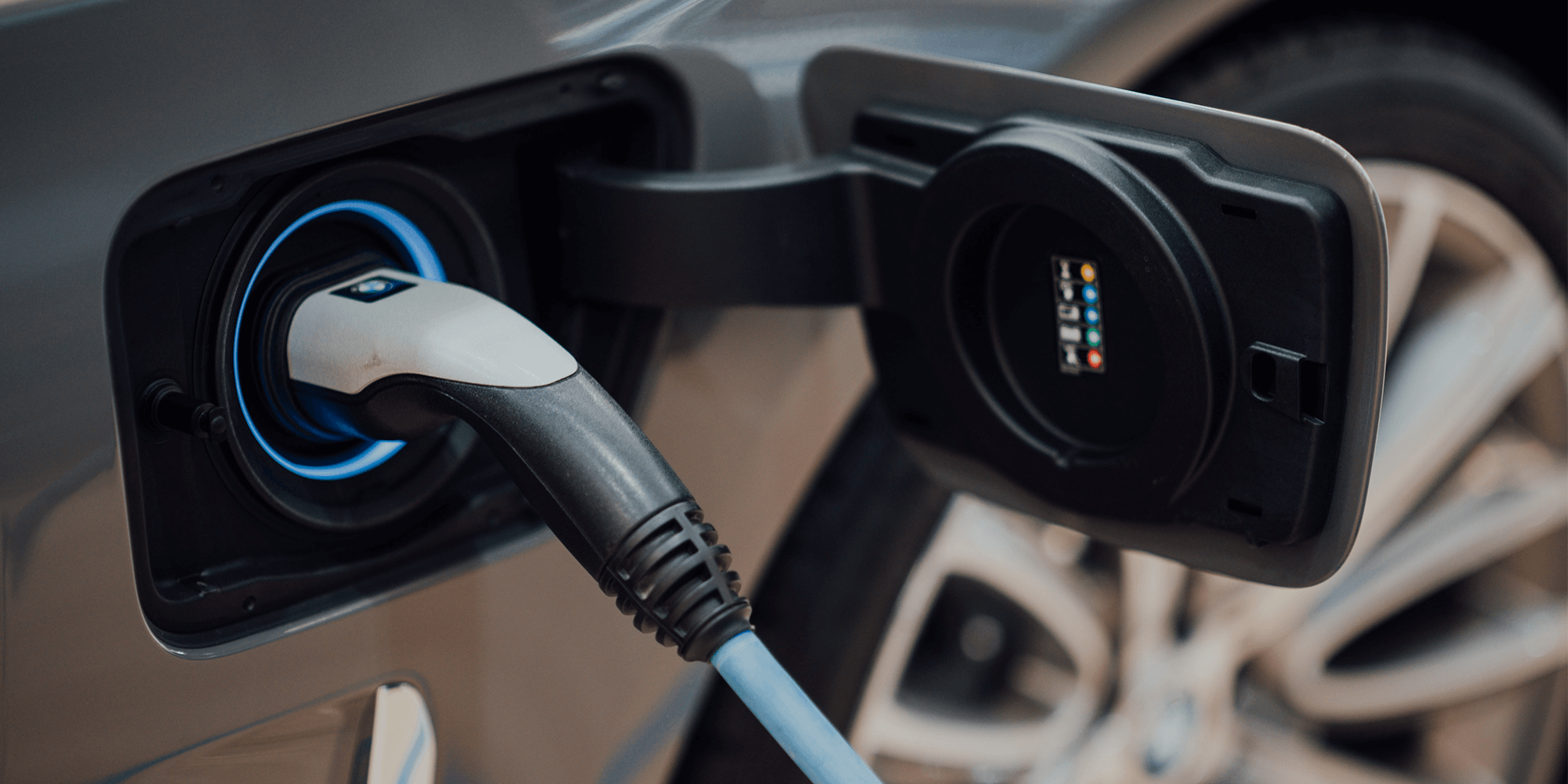

As the climate crisis captures the attention and efforts of scientists, innovators, governments, and cleantech developers, a sense of urgency is growing. OEMs are doubling down on their electrification commitments and battery manufacturers are building plants across the globe.

The latest numbers by Benchmark Mineral Intelligence (October 2021) projected 4,625 GWh of global lithium-ion battery production capacity in the pipeline by 2030. That does not account for fuel cell applications, grid optimization, nor high-efficiency materials. The list of climate technologies keeps extending by the hour. And there is a constant variable: minerals and advanced materials required to build, power, and support these solutions.

It is no surprise miners are rushing to develop critical mineral deposits in time to meet the booming demand. The opportunity is unprecedented. Indeed, our sector represents a key enabler for global decarbonization.

But the opportunity has its counterpart. The urgency to attain a low-carbon future cannot be achieved on the back of the environment. Today’s mining practices have been strengthened by scientific knowledge, shared best practices, increased transparency, as well as stringent regulation and global standards. We must continue to elevate this stewardship.

But the opportunity has its counterpart. The urgency to attain a low-carbon future cannot be achieved on the back of the environment. Today’s mining practices have been strengthened by scientific knowledge, shared best practices, increased transparency, as well as stringent regulation and global standards. We must continue to elevate this stewardship.

If water quality values, tailings management indicators, and community socioeconomic impacts have increasingly been accounted for in our sector’s performance, it is time to focus on a different bottom line.

Mining is an energy-intensive industry. According to the Center for Social Responsibility in Mining, “greenhouse gas (GHG) emissions associated with primary mineral and metal production was equivalent to approximately 10% of the total global energy-related greenhouse gas emissions in 2018”.

The energy transition presents us with more than favorable market perspectives. It provides us with new solutions to conduct our business. Electrification is here. Not just in urban centers and on expressways, it is being perfected for various terrains, jobs, and vehicles.

It is time to walk the talk on decarbonization.

Walking the Talk on a Net-Zero Future

At Nouveau Monde Graphite, we set our minds on sustainability from the onset. For we acknowledged the responsibility of developing a non-renewable resource. For we knew that the commercial outlook of our Matawinie mining project was tightly linked to the global electrification. For we recognized the immense opportunity of having access to abundant, affordable, and clean hydropower. For we understood the growing demand from manufacturers and consumers for responsibly sourced products.

Hence, we committed to an all-electric fleet – what is expected to be a world’s first for an open-pit mine – in 2017. Most said it was idealistic. Some said it was unachievable. And a few dared to plunge in the adventure, joining our ranks as employees, consultants, and business partners.

Today, we are seeing our vision come alive in front of our very eyes. In June 2021, we signed an agreement with Caterpillar Inc. for the development, testing and production of Cat® “zero-emission machines” for our Matawinie graphite mine. This future fleet will be supported by a dedicated hydroelectricity power line.

When fully operational, our fleet should result in approximately 85% less direct GHG emissions from our mining operations.

Now that is precisely the new type of metrics we should be focusing on. Low-carbon – even net zero might I suggest – operations to sustainably extract and transform the minerals for tomorrow’s cleantech.

Technically Achievable, Economically Sound & Environmentally Responsible

Electric mining is very much underway, in both open-pit and underground environments, with successful examples across continents and weather conditions.

Our 2018 43-101 Feasibility study demonstrated the viability as well as long-term savings of deploying an all-electric fleet at our Matawinie mine. The commercial benefits are complemented by greater ease of securing a social license to operate thanks to reduced noise, improved air quality and superior trustworthiness as an ESG-focused corporate citizen.

Combined with our ecotechnologies for value-added transformation of our graphite concentrate, the adoption of all-electric operations enables us to bring to market anode material with a 50x-smaller GHG footprint than common spherical graphite.

We are proud to be a driving force as we strive to meet our carbon neutrality commitments while maintaining our operations’ productivity and efficiency standards.

Hurdles to implement do exist, but they should not stand in the way of modernizing mining fleets.

Going electric could mean significant upfront costs but also considerable operational expenditure savings, as well as environmental and social benefits down the road.

Needless to say that we are accountable for more than our financial results and ESG indicators. We are answerable for the part we are playing in the global fight against climate change.

Analyses, studies, and commitments are no longer sufficient. The crisis is accelerating.

The mining industry, as a catalyst to the global decarbonization, must grasp the full potential for engaging in the transition and supplying the world with responsibly sourced materials.

While efforts ought to multiply, our industry’s bottom line must be brought down to 0.

THIS PIECE APPEARED AS A FOREWORD IN MINING MAGAZINE FUTURE FLEETS REPORT.